Audit Process

Direct import, non-branded and private label suppliers are required to declare to us all factories involved in the production of merchandise for Wal-Mart. Once the supplier declares their factories to us, our factory audit process begins by scheduling and conducting an initial audit. After the on-site audit is completed, the factory is provided a report on the findings, which contains suggestions for correcting any violations. Depending on the findings in the audit report and the audit rating, a follow-up audit may be required and scheduled.

Audit Report

Factory audits contain questions that cover a broad range of social and environmental criteria that help guide our assessment of a given supplier factory. The audit questionnaire is based on our Standards for Suppliers, the commitments our leadership made in Beijing, and is in alignment with the Global Social Compliance Program. Notably, the 2009 questionnaire contains more than 150 questions and includes expanded environmental criteria – increased from 21 to 51 environmental questions.

Factory Ratings and Results Overview

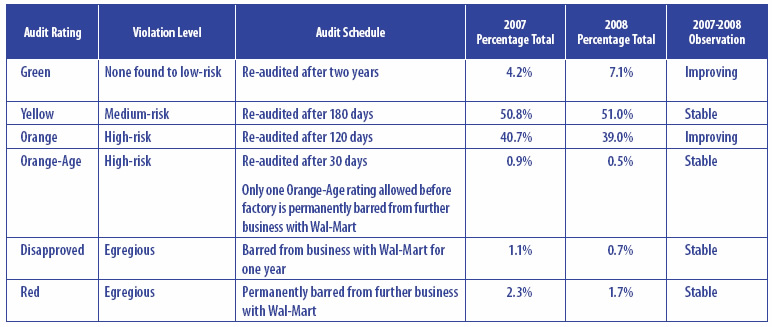

Following the completion of a factory audit, a color-coded system is used to signify the overall assessment of the audit findings. The color assigned to the factory would depend on the number and type of violations discovered during the audit. Factories with few or less serious violations receive our highest rating — green. The factories having progressively more severe or numerous violations receive lower ratings, from yellow, to orange and red. The table below illustrates the ratings and their respective re-audit schedules, and provides the percentage of the overall results of the Ethical Standards audits in 2007 and 2008 that correspond to each rating.