Logistics

OVERVIEW

Our Company operates one of the largest private trucking fleets in both the U.S. and the U.K., and these fleets support a number of strategically organized Wal-Mart distribution centers within those countries. Today, our Logistics Division is working hard to make our entire fleet more efficient, develop the most efficient routes, increase the number of cases per load and create more sustainable distribution centers.

These initiatives are helping us travel fewer miles. But perhaps most importantly, our initiatives are helping us bring products more efficiently and inexpensively to our customers, reducing our overall impact on the environment and helping us deliver on our mission of saving people money so they can live better.

ACCOMPLISHMENTS IN OUR TRUCKING FLEET

Americas

United States

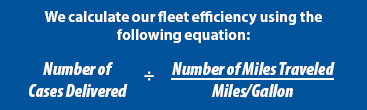

In 2008 and early 2009, we celebrated a number of significant accomplishments in our U.S. Logistics Sustainable Value Network (SVN). Perhaps most notable, we surpassed our goal set in 2005 to make our fleet 25 percent more efficient by the end of 2008. We calculate our fleet efficiency by first dividing the number of miles we traveled by the average fuel efficiency we achieved in our trucks as measured in miles per gallon. This leaves us with the amount of fuel we used to travel those miles. We next take the number of cases we delivered during the same time period and divide it by the amount of fuel we used to deliver the cases. By calculating our efficiency in this way, we can tie in all of the aspects that play a role in our fleet efficiency. Overall, we reached a 38 percent increase in efficiency by working within our SVN and with our partners to install fuel-saving technologies on our trucks, load our trucks and cases more efficiently, improve our routing and eliminate the number of empty miles our trucks traveled.

These initiatives enabled us to deliver 3 percent more cases to our stores while driving 7 percent, or about 90 million, fewer miles in absolute terms. If we had driven at the same efficiency level and used the same routes and loading methods in 2008 as we did in 2007, we would have driven nearly 140 million more miles to deliver those extra cases.

By driving fewer miles, we avoided adding 200,000 metric tons of CO2 into the atmosphere. These efficiency improvements also resulted in fewer trucks being on the road, reducing wear-and-tear on roads, highways and bridges. Additionally, our changes helped us save almost $200 million last year. Now, we are working toward our goal to double the efficiency of our fleet by 2015 compared to our fleet in 2005.

While we continued to make our existing trucks more efficient by improving engine calibration and installing technologies such as auxiliary power units (APUs), we have made additional efforts to explore and integrate aerodynamic and alternatively fueled trucks into our fleet. In 2008, we added more than 1,100 aerodynamic trucks to our fleet to further improve our fleet efficiency. We plan to add 1,300 more in 2009.

We still have a lot of progress to make before we reach our goal to double the efficiency of our fleet by 2015, but we believe we are moving in the right direction to meet that goal.

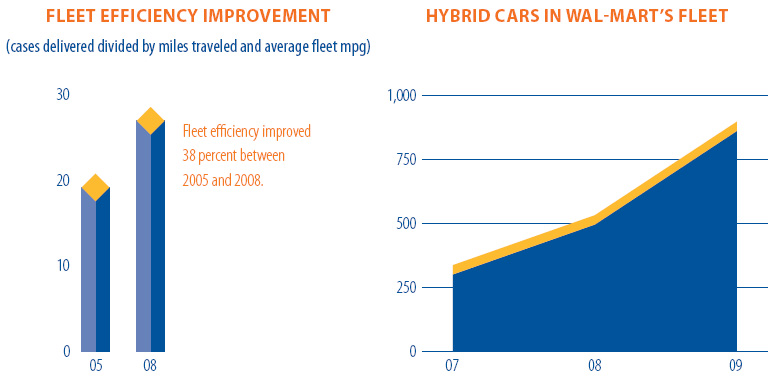

In addition to transporting products, we have a fleet of passenger cars used to transport associates. We committed to purchasing an additional 300 hybrid cars for our passenger fleet in 2009. Currently, we have 860 hybrids, which is almost 17 percent of the fleet. Click here to learn more about our efforts in logistics.

Europe

United Kingdom

By the end of 2009, our ASDA stores aim to have their truck fleet emit 40 percent fewer carbon emissions — measured by volume of cases shipped — than their fleet emitted in 2005. This fleet improvement program is called "Fewer and Friendlier Road Miles" and is helping ASDA reduce the number of empty trucks on the road and integrate new technologies into the fleet.

To reduce the number of miles driven, ASDA developed initiatives to increase the number of backhauls and fronthauls they run. Backhauls enable ASDA to fill empty trucks traveling between the stores and distribution centers to collect shipments from suppliers for direct delivery to the distribution centers. In 2008, this initiative saved ASDA approximately 1.17 million miles in ASDA's supply chain, reducing almost 1 million empty miles for ASDA trucks alone. ASDA also uses a fronthaul initiative, in which suppliers deliver ASDA's goods, as opposed to an ASDA truck, in the event the suppliers' drivers are already headed to that destination. In 2008, this saved ASDA 1.4 million road miles. Total road mileage saved in 2008 through ASDA's logistics sustainability efforts was 8 million miles and eliminated the production of 10,222 tons of CO2 from its trucks.

Also included in the "Fewer and Friendlier Road Miles" program are the addition of new technologies and using other transportation methods to move products. ASDA is improving efficiency and saving road miles by making use of trains and double-trailers. Each month, ASDA displaces 625,000 road miles and eliminates 475,000 road miles, respectively, by utilizing these large-load platforms. ASDA is also using synthetic oils, fuel additives and integrating technological solutions into the trucks to improve efficiency. One technology called Isotrack is a computer installed in cabs that analyzes driving patterns and their effect on fuel efficiency.

Asia

Japan

In Japan, Seiyu aims to reduce the amount of fuel needed to transport 1 ton of goods per kilometer by 25 percent by 2012. Seiyu measures the amount of fuel required to carry 1 ton of goods 1 kilometer and is tracking well toward the goal. Between 2007 and 2008, Seiyu was able to transport 16 percent more goods over the same amount of distance by using more efficient routing and loading techniques for trucks, and consolidating operations and deliveries. Last year, their efficiency improvements led to a decrease in CO2 emissions by more than 13 percent. Going forward, they plan to further improve their fleet efficiency by expanding the use of local products and continued logistics optimization.

DISTRIBUTION CENTER IMPROVEMENTS

Our distribution centers around the world are also playing a role in our efforts to increase the efficiency of our operations. The strategic placement of our distribution centers helps increase the efficiency of our fleet by cutting down the number of miles that products travel before reaching one of our stores. And innovative technologies being added to existing and new distribution centers help reduce our energy use and greenhouse gas emissions.

Americas

United States

Walmart has more than 140 distribution centers that service more than 4,200 stores across the U.S. We believe that all of our buildings should operate as efficiently as possible, and that's why we're also working to reduce energy consumption at our distribution centers.

Our improvements include:

- Retrofitting Lighting Fixtures: Replaced the lighting fixtures in more than 100 of our distribution centers to use T5 fluorescent light bulbs. Using these bulbs, we saved more than 200 million kWh of electricity.

- Using Energy Demand Monitoring Systems: Although the distribution centers themselves run nearly 24 hours a day, not all of the equipment needs to run all the time. Our energy demand monitoring system enables us to turn off lights and equipment when they are not in use. We use motion-sensor lighting and a similar system that controls conveyor belts.

- Integrating Glycol Cooling into the Refrigeration System: In the past two years, five distribution centers were retrofitted to feature HVAC units that use a glycol cooling loop, which is supported entirely by the refrigeration system. Not only does the system keep the perishable foods cold, but also cools the entire distribution center.

- Rapid Doors: We recently completed successful testing and have started integrating rapid-operating doors that create a solid barrier between rooms that require different temperatures in the grocery distribution centers. These doors help us save energy by remaining closed when there is no traffic in and out of the room, but open very quickly when an associate approaches.

- Variable Frequency Drives (VFDs): Similar to the energy demand monitoring system, our refrigeration systems adjust their output based on the current need. If there is not as much to cool, then the systems do not need to run at their full capacity. By installing Variable Frequency Drives (VFDs), we are able to match the speed of operation to the current load required.

- Solar Panels: In California, we completed the installation of solar panels at one distribution center in Porterville and will be completing a second location in Apple Valley during the second quarter of 2009. In Porterville, the panels were installed on the roof of the facility and will supply approximately 600 kW of power. The ground-mounted solar panels in Apple Valley will cover a nine-acre field and supply 1 megawatt (MW) of power.

Europe

United Kingdom

Given the strategic placement of ASDA's distribution centers, the distance between the stores and the distribution centers averages only 50 miles. This helps ASDA reduce the number of miles trucks travel and saves fuel.

Asia

China

In China, Wal-Mart opened a distribution center in Tianjin which won the 2008 Green Supply Chain Award from the China Supply Chain Council. The 455,000-square-foot distribution center has a number of sustainable features that help reduce CO2 emissions and energy and water consumption. The distribution center includes solar panels and wind turbines that produce renewable energy. Solar water heaters installed at the facility can provide 1.7 tons of hot water each day. Energy efficiency improvements include the installation of efficient T5 light bulbs, daylight harvesting and an HVAC system with improved energy consumption.