Examples of Industry-Leading Technologies Used in Wal-Mart Stores Around the World

Energy Management System (EMS) In the U.S., we employ a centralized Energy Management System (EMS) to monitor and control the heating, air conditioning, refrigeration and lighting systems for all stores and Sam's Club locations from our Home Office in Bentonville, Arkansas. The EMS enables us to constantly monitor and control energy usage, analyze refrigeration temperatures, observe HVAC and lighting performance, and adjust system levels from a central location 24 hours a day, seven days a week.

Daylight Harvesting

Many Wal-Mart stores and distribution centers around the world include a daylight harvesting system, which integrates skylights that dim or turn off interior electric lighting in response to the amount of daylight available. By using dimmable T-8 fluorescent lamps, electronic continuous dimming ballasts and computercontrolled daylight sensors with approximately one skylight per every 1,000 square feet, we can take full advantage of natural light when available. Daylight harvesting is estimated to save up to 75 percent of the electric lighting energy used in the sales area of a supercenter during daylight hours. Each daylight harvesting system is estimated to save an average of 800,000 kWh per year, which is enough energy to power 73 single-family homes (11,020 kWh average annual usage) for an entire year.

Light-Emitting Diodes (LEDs)

In 2007, after being tested in our experimental stores in the U.S., LED lights in refrigerated cases became popular additions in many of our stores around the world. LED refrigerated case lighting technology is estimated to provide a more than 70 percent energy-efficient operation than fluorescent case lighting. The total energy savings for LED refrigerated case lighting is estimated to be more than 90,000 kWh per year for an average supercenter. Therefore, each store with LED case lighting saves enough energy to power almost eight single-family homes for an entire year. The lifespan of LED refrigerated case lighting is projected to be at least six years beyond conventional fluorescent refrigerated case lighting, which must be replaced, on average, every two years in a refrigerated case environment. This life expectancy allows for a significant reduction in re-lamping and maintenance costs. Additionally, LEDs contain no mercury, perform well in the cold, and produce less heat than fluorescent bulbs — heat which must be compensated for by the refrigeration equipment.

Reducing Water Consumption

Some of our stores also have integrated advanced water- and energy-saving technologies in the restrooms. The restroom sinks in some newly constructed locations use sensor-activated, half-gallon-per-minute, high-efficiency faucets. Electronic sensors regulate a maximum 10-second run time per cycle. In addition, there are water turbines built into each faucet. During use, water flowing through this turbine generates the electricity needed to operate the sensors.

We are also installing high-efficiency restroom urinals and toilets that yield reductions in water usage. Automatic flush valves on the toilets have water turbines similar to the low-flow faucets, which generate the power required to activate the flush mechanism. These turbines not only save energy, but also save material by eliminating the need for electrical conduits and wiring otherwise required to power automatic flush valve sensors.

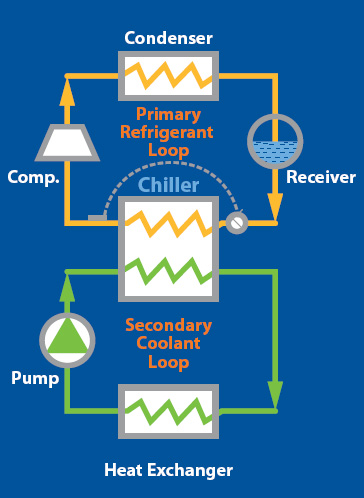

Secondary Loop Refrigeration System

As these high-efficiency stores were opened throughout 2008, we began monitoring their performance and expect to have data to report in our next global sustainability report. We expect that some of the improvement in energy efficiency will result from a new secondary loop refrigeration system, combined with an advanced water-source heating, cooling and refrigeration system. The technology uses a non-refrigerantbased solution to cool refrigerator and freezer cases, resulting in a 90 percent reduction in refrigerant. These second-generation pilots represent the first time secondary loop refrigeration technology has been paired with a water-source heating and cooling system in retail.

Also in 2008, we opened our most energy-efficient store in the U.S., the latest-generation high-efficiency store in Las Vegas, Nevada. This store is designed specifically for the Western climate, meaning the efficiency gains are made possible by innovations designed for the conditions of the region. The store is expected to use up to 45 percent less energy than the baseline supercenter by featuring advancements in heating, cooling, refrigeration and lighting to conserve energy and reduce greenhouse gas emissions. Specifically, the store features the integrated water-source format system that we evaluated in previous pilot stores, but it has been adapted to the unique local climate and includes evaporative cooling and radiant flooring technologies. This technology naturally reduces the temperature of water by pumping it through roof-mounted cooling towers and running the cold water underneath the retail floor to cool the shopping area. Together, the systems provide a comfortable shopping environment for our customers while using less energy.

We have also been working for several years to make our building materials more sustainable. We already require that all newly constructed stores and Sam's Club facilities either replace 15 to 20 percent of their cement with fly ash, a waste product of coal-fired electrical generation, or replace 25 to 30 percent of their cement with slag, a waste product of steel manufacturing. Replacing cement with waste products such as slag or fly ash can help offset the greenhouse gas emitted in the cement manufacturing process. In 2008, we were able to replace 18 percent of the cement with fly ash and 22 percent with slag.

In 2008, we incorporated several additional sustainable components to our buildings. For example, all new Walmart stores and Sam's Club facilities are built with exposed concrete floors, which eliminate the need for most chemical cleaners, wax strippers and propane-powered buffing. We are also improving the energy efficiency of our distribution centers. Click here to learn more.